13

Key Facts

- Low investment costs Up to 8-fold parallel machining for short cycle times Fast tool changes Almost any internal geometry possible

- No mechanical or thermal stress on the component No vibrations in the manufacturing Low-noise process Minimal footprint

Categories

Fully-automatic rifles Handguns Semi-automatic rifles

Product information

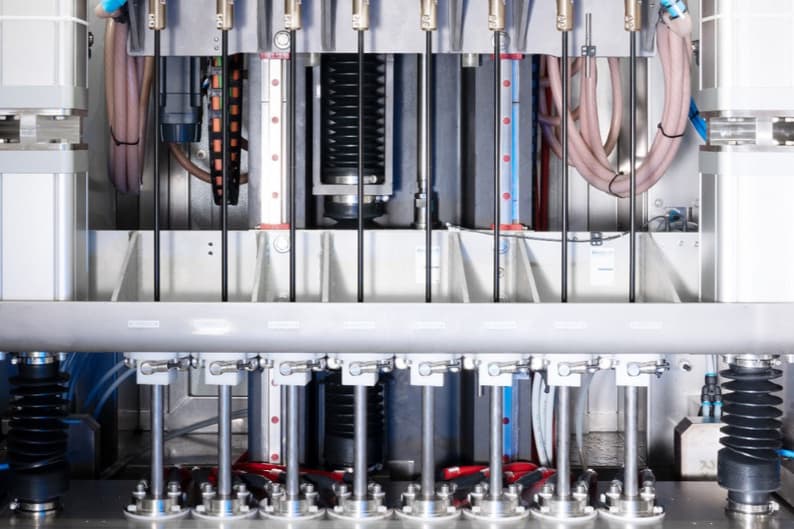

ECM is the ideal technology for machining rifle barrels. Employing a special machine solution in the PI machine produces high-precision internal geometries on short and long barrels.

EMAG ECM now uses a clever technological concept developed specifically for rifling. First, where the tool is concerned, this means that the (very narrow and elongated) tool cathode generates the desired internal geometry of the barrel with high precision. A wide range of very different geometries are possible, for example “polygonal,” “progressive” or “standard rifling.” Within the machining area, there are eight of these cathodes inside a compact module.

It is faster than the fre ...Watch our product video

ECM Rifling Video